Damping And Absorption Capacitor

LY-2kVDC-0.25μF

The agreement on damping and absorption capacitor project should be kept secretly by both parties and must not reveal to any other third party. The agreement documents in duplicate come into effect once signed by both party’s representatives and stamped with company chop.

Party A: Contact: (DD/MM/YY)

Party B: Contact: (DD/MM/YY)

1.Product Usage

This product is mainly used to semi-conduct switching ,protection, filter and storage energy in the power electrical device.2.Product features

2.1 Features: The capacitor contains high-quality polypropylene film and low temperature insulation impregnant, none PCB. Electrodes are made of special aluminum foil for electronic; Adopt non-inductive roll artwork. Bear transient heavy current and HV impulse without capacitance loss. low dissipation,well sealed, good heat dissipation, long life-time, anti-explosion and high security.

2.2 Appearance: Frosted aluminium oxide housing,good look. The features of anti-corrosive PET label, no peel-off, no color fading, small size, light weight, and easy installation and etc.

3.Referenced Standard

3.1 GB/T 17702.1-1999 Electric power capacitor, part 1, general principles.

3.2 GB/T 17702.2-1999 Electric power capacitor, part 2,Experiments of fuse isolation, destruction test, self-healing and durability requirement.

4. Technical parameter

4.1 Main parameter

4.1 Under natural air to cool down: The maximum temperature of the operating capacitor housing is 70℃

4.2 Elevation:≤1000m

4.3 Relative humidity:≤95%

4.4 Rated Voltage:UN=2kVDC

4.5 fundamental frequency:50Hz

4.6 rated capacity:CN=0.25μF

4.7 Capacity Tolerance within ±10%

4.8 Tangent of the loss angle of a capacitor tanδ(1kHz)≤0.0005

4.9 Insulation resistance: RC≥3000S

4.10 Terminal test voltage:UTTDC=4kVDC, 10S

4.11 Voltage between terminal and housing:UTTDC=5kVDC,10S

4.12 Housing: Cylindrical aluminum housing

4.13 Sealing test: No leakage in 4 hours under rated temperature of 75℃±5℃

4.14 Discharge test between terminals: 1.1 voltage,10s bear 20 times DC charging and discharging in polarity, Without breakdown and capacitance loss.

4.2 overload

The capacitor can runs as per below form, in which the overvoltage of above 1.1Un is based on no obvious reduction of capacitor’s life time.

|

OverVoltage |

The longest duration time in one day |

Remark |

|

1.1UN |

The overload time 30% |

system adjustment |

|

1.15UN |

30min |

|

|

1.2UN |

5min |

|

|

1.3UN |

1min |

system switch |

|

1.5UN |

100ms |

5.1 In-house installation usage

5.2 Installation location elevation ≤1000m

5.3 Ambient humidity less than 85%

5.4 Temperature category: -40/D

5.5 The capacitor long running temperature less than 55℃

5.6 No strong metal corrosive steam or air in the surrounding.

5.7 No intense mechanical shaking, no explosion or inflammable materials

5.8 Installation should avoid high magnetic field

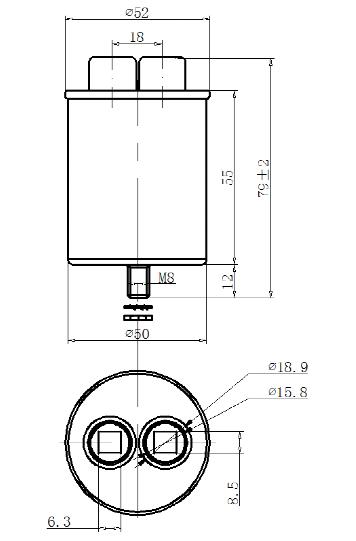

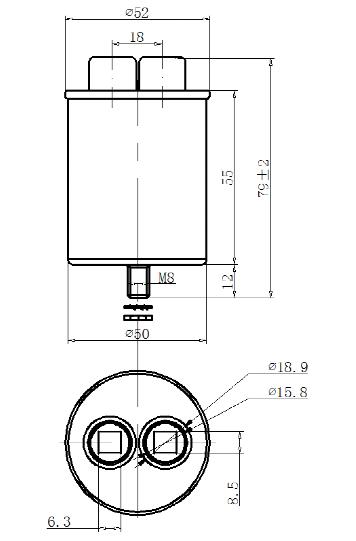

6. Product dimension (refer to insert drawing at the end)

7. Ex-factory released check and test

7.1 Ex-factory eleased check

7.1.1 Cosmetic check

7.1.2 Capacitance check

7.1.3 Loss angle(tanδ)check

7.1.4 Terminal voltage check

7.1.5 Voltage between terminal and housing check

7.1.6 Sealing check

7.2 Acceptance check

7.2.1 Delivery list

7.2.2 Test report

7.2.3 Qualified certificate

7.2.4 Installation IM

7.2.5 When the customer receives the capacitor, need to check the appearance, if any deformation and damage of housing, and the insulator is vertical to insulation housing, and the correctness of label.

7.2.6 If with test equipment, can test the capacity if within 3% allowance which complies with the rating label and test report.

8. Transportation and storage

8.1. Notice of transportation

8.1.1 Must be transported with package well packed.

8.1.2 Avoid crash or friction

8.2 Notice of storage

8.2.1 Stored vertically, no heat source or corrosive air around.

8.2.2 No stack up by using any upholder between capacitors.

9. Installation and protection

9.1.1 The capacitor can be installed, vertically or horizontally, in the place where the aluminum housing will be protected well. Space between each capacitor must be more than 50mm, and is draughty.

9.1.2 Make sure no shaking of the capacitor and more than 50mm distance of any heat resistance.

9.1.3 There should be proper protection of the capacitor group, like fuse or relay and so on.

9.1.4 Need manual discharge of the capacitor when it is not connected in the whole electric system.

10. maintenance

10.1 It is suggested to check the appearance of the capacitor every day, if any problem may happen, like electrolyte leakage or connector heats

10.2 Record the temperature of the capacitor’s installation position.

10.3 Capacitor’s regular check can be 1time/year, and varies according to the actual operation condition.

10.4 Check the capacity of the capacitor, and record each time to compare with previous record. If there is obvious change, exchange it with the same specification capacitor. And check each capacitor if any leakage or pollution. Clean it when polluted.

10.5 Check all terminals if well connected. Deal with it timely to avoid possible accident.

11. Replacement

11.1 When no capacitance

11.2 Breakage of the housing

11.3 Electrolyte leakage

11.4 Usage more than 10 years.

12. Quality guarantee and sales service

With the quality policy as “Elaborative making, scientific management, continuing improvement and customer satisfaction”, and in order to enhance our worldwide credibility to realize the company’s strategic goal, we make the promises to all our related customers as below:

12.1 More improvement on quality system and enhancement on quality management to ensure each product is qualified with IEC standard, national standard and electric power industrial standard.

12.2 Make sure to provide customer with good service in pre-sales, sales and after-sales; and if within the period of “Chinese national three guarantees” any complaint about quality issue will be replied within 24 hours.

12.3 Apply with the “Chinese national three guarantees”. If any quality issue happens within the valid time 1 year, we will strictly perform according to the contractual obligations. If it exceeds the guarantee 1 year time, customer can take the warranty card for repair. NO quality guarantee in case of damage of installation, operation and maintenance caused by human factor.

-

Product drawing: